Author: Site Editor Publish Time: 2025-12-23 Origin: Site

When it comes to customizing promotional items such as T-shirts, heat transfer vinyl (HTV) and screen printing are two of the most common techniques. Both methods offer their own advantages, but they cater to different needs. If you're looking to brand apparel for your company, understanding the differences between these techniques is essential. Here's a closer look at each method to help you choose the right one for your project.

Printed apparel is a widely popular category for promotional items, with T-shirts being a favorite. From casual to formal styles, promotional clothing serves as a walking advertisement for your brand. When it comes to customizing shirts, the two primary methods used are heat-transfer printing and screen printing. While both techniques transfer designs onto fabric, there are notable differences in their processes, benefits, and drawbacks.

Let's dive deeper into each method:

Screen printing, often known as silk screening, involves using a mesh screen to transfer ink onto fabric. The method dates back to ancient times, but its modern form was developed in the early 20th century. It wasn't until the 1960s that screen printing became widely used, thanks in part to artists like Andy Warhol.

To begin the screen printing process, a stencil is created on the mesh screen. Ink is then spread over the screen with a squeegee, and it passes through the screen to create the design on the fabric. Each color in the design requires a separate screen.

Screen printing is a straightforward process, although it can be time-consuming for designs with multiple colors. However, the end result is a durable design that stands up to repeated washes.

Durability of Screen Printing:

Screen printing is typically more durable compared to heat transfer, especially when it comes to washing and abrasion resistance. The ink penetrates the fabric, making it more resistant to fading and cracking even after multiple washes. A screen-printed T-shirt can endure 40 to 50 machine washes, depending on care. While it's challenging to pinpoint an exact duration, screen printing is known for its durability. In general, a well-executed screen print on high-quality materials can last for several years, even with regular use and proper care.

How Does Screen Printing Work?

Screen printing can be done manually or by machine. Regardless of the method, the process follows these basic steps:

• Create a design

• Choose a screen and mesh count

• Expose the emulsion to create a stencil

• Prepare the screen for printing

• Apply ink to the screen

• Dry and cure the design

Once the design is applied, the shirts are dried and inspected to ensure everything is aligned correctly. Screen printing is ideal for bulk orders and is known for producing vibrant, long-lasting prints.

Benefits of Screen Printing:

• More economical for larger quantities

• Softer fabric feel compared to heat transfer

• Longer-lasting designs

• Vibrant colors, even on dark fabrics

Drawbacks of Screen Printing:

• Limited to simpler designs with fewer colors

• Can be messy and time-consuming during setup

• Higher setup costs, making it less ideal for small orders

• Not suitable for complex images like photographs

• Requires more chemicals and equipment than heat transfers

Images can turn out blurred. Detailed photographs or graphics with specific gradients or shades may not come out as focused or exact due to the limitation of colours. Another factor is the thickness of the garment. Costly method for small on-demand orders.

Related read: What Exactly Is Silk Screen Printing?

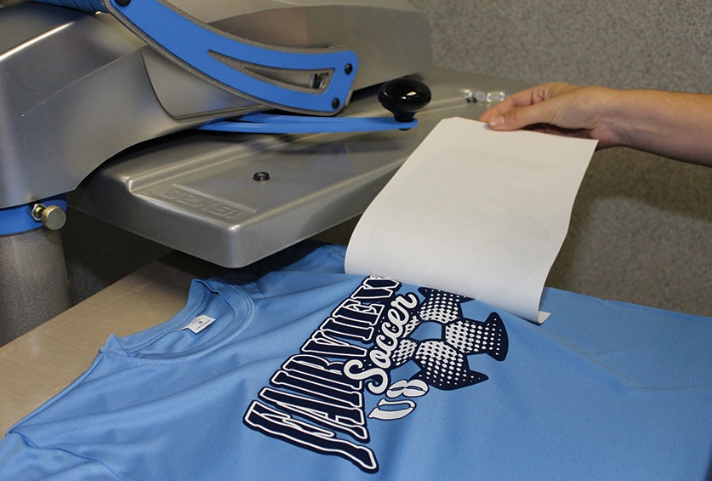

Heat transfer printing has gained significant popularity in the past two decades. This method uses heat and pressure to transfer designs onto fabrics. There are two primary types of heat transfer printing: vinyl heat transfer and digital print heat transfer. Both require a heat press machine to apply the design to the material.

Vinyl Heat Transfer

This method involves cutting designs or letters from vinyl sheets. The individual pieces are arranged and then pressed onto the fabric using heat. Vinyl heat transfer is best for small graphics, like slogans or names on jerseys, and is commonly used for sportswear.

Digital Print Heat Transfer

Digital heat transfer uses a process similar to printing on paper. The design is created on a computer and printed onto transfer paper using special solvent ink. Once the transfer paper is pressed onto the fabric with heat, the image adheres to the material. This technique is perfect for intricate designs with multiple colors.

Heat transfers are particularly suitable for smaller orders and complex designs, as the process is easier and faster compared to other methods. This makes it a cost-effective option for small-scale customization.

Benefits of Heat Transfer Printing:

• Ideal for small print runs

• Works well with intricate and multi-colored designs

• Relatively low setup costs

• High-quality image resolution

• Allows for easy customization

• Environmentally friendly process

Drawbacks of Heat Transfer Printing:

• Not as effective on dark fabrics

• Designs tend to fade quicker than screen-printed designs

• The fabric feels stiffer compared to screen printing

• Colors may not appear as vibrant on dark fabrics

Some heat press printed products, especially vinyl heat transfer products, are prone to cracking and fading. Heat transfer printing can be a budget-friendly way to produce small product runs, but it is often more expensive than screen printing for bulk orders.

When comparing heat transfer and screen printing, there are a few factors to consider, such as durability, image quality, and cost-effectiveness.

Durability

While heat transfer images might look sharp when first applied, they tend to crack and fade over time, especially with frequent washing. On the other hand, screen printing provides a much more durable result, with designs that last longer and retain their vibrancy.

In general, a well-executed screen print can last for several years if properly cared for. One key factor in determining the lifespan of a screen-printed design is the quality of the ink and the printing process.

Resolution

In terms of resolution, heat transfer offers better quality initially, as the designs are often crisper and more detailed. However, screen-printed designs, while slightly less crisp initially, tend to maintain their appearance for a much longer time.

When Should You Choose Heat Transfer Printing?

Heat transfer printing is ideal for:

• Small orders or one-off designs

• Complex designs with multiple colors

• Projects involving dark fabrics

• Customers looking for more environment-friendly options

When Should You Choose Screen Printing?

Screen printing is best for:

• Large orders (500+ shirts)

• Designs with a limited number of colors

• Long-lasting, high-quality prints

• T-shirts that need to withstand frequent washing

Both heat transfer and screen printing are great options for customizing T-shirts and other apparel items. Your choice depends on the specifics of your order—whether it's a small or large batch, the complexity of the design, the colors involved, and the durability required.

If you're creating a one-off custom design or have a small batch order, heat transfer might be the way to go. However, for larger orders and designs that need to last, screen printing offers a more durable and cost-effective solution. The extensive labor required to create, separate, coat, expose, and register screens makes the screen printing process inefficient for small quantity orders with lots of colors. That's why screen printing more expensive

For large-scale productions, designs with solid colors, and a focus on durability, screen printing is often the preferred choice. On the other hand, heat transfer is suitable for smaller quantities, intricate designs, quick turnarounds, and designs that require gradients or photographic elements. The right choice depends on several factors:

• Is your design complex? If so, heat transfer might offer a better, cost-effective solution.

• Does your design include multiple colors? Heat transfer can handle that more easily.

• Are you working with dark-colored fabric? Choose screen printing for brighter colors.

• How many shirts are you ordering? For smaller quantities, heat transfer is cheaper; for larger orders, screen printing is more cost-effective.

• Is long-lasting quality important to you? Screen printing will deliver a more durable result.

In conclusion, both techniques have their place depending on your specific needs. Screen printing excels in larger orders with simpler designs, while heat transfer is best for intricate and smaller quantities. Consider these factors carefully when making your decision, and you'll be able to select the right method for your promotional apparel.

As a leading supplier to garment manufacturers, textile factories, printing companies, and advertising agencies globally, Hanze Ltd specializes in providing high-quality silk screen printing products. We offer a wide range of printing frames, mesh screens, and related accessories tailored for efficient and precise silk screen printing operations.

Our products are designed to meet the needs of businesses requiring durable, reliable, and customizable printing solutions. Whether you're looking for top-tier frames, specialized mesh screens (NBC Screen Printing Mesh), or other essential materials for your printing process, Hanze is your trusted partner for high-performance products.

Explore our collection of silk screen printing products today or contact us to discuss your specific requirements. Hanze Ltd is committed to offering one-stop solutions to help streamline your production processes and deliver optimal results.

FAQ:

1. Can a Heat Press Be Used for Screen Printing?

A heat press is a versatile tool with a wide range of applications. Many screen printing professionals start by using heat presses to transfer designs onto items like T-shirts, tote bags, and other clothing. Heat presses are also effective for curing garments and are commonly used for printing at live events.

2. Do Screen Print Transfers Expire?

Screen print transfers can remain in good condition for several years if stored correctly. Keeping them in a safe environment prevents physical damage. Additionally, wrapping them in protective materials helps maintain the colors and image quality, ensuring they last for a long period.

3. What Makes Screen Printing the Better Choice?

Here are ten advantages of screen printing in the printing industry:

• Cost-effective for large quantity orders

• Known for high durability and top-notch quality

• Produces vibrant colors and works well with specialty inks

• Can be used on a variety of printing surfaces

• Scalable and fast, making it ideal for bulk printing

• Ensures consistent prints with superior results

• Offers unique customization options

• Delivers excellent print quality

• Provides a soft, natural feel on fabrics

• Increases overall efficiency when paired with the right equipment

4. Will Screen Printing Fade Over Time?

There are several factors during the printing process that can cause a screen-printed design to fade. For instance, if the ink used is of poor quality or not compatible with the fabric type, the design may eventually peel, crack, or lose its color. Inadequate curing time or insufficient heat during the printing process can also contribute to premature fading.

5. What Is the Lifespan of a Heat Press Shirt?

Heat transfer shirts made using standard transfer paper generally last for about three washes before noticeable deterioration begins. After that point, the design may start to break down significantly. These shirts are best suited for short-term use or one-off occasions where only a few wears are needed.