Author: Site Editor Publish Time: 2025-09-19 Origin: Site

DTF (Direct-to-Film) printing has taken the garment decoration world by storm—delivering vivid, soft-touch designs across a wide variety of fabrics. But amid its growing popularity, one critical question remains for decorators and apparel businesses alike: how long do DTF prints actually last?

In the world of custom printing, durability isn't just a technical detail—it's a reflection of your brand's quality and reliability. No customer wants a vibrant tee that fades after three washes. And no business wants to risk returns, complaints, or loss of trust due to short-lived designs.

This guide breaks down everything you need to know about DTF print longevity, backed by real-world testing, technical best practices, and industry comparisons. Whether you're scaling a DTF business or just exploring the method, this is your roadmap to long-lasting success.

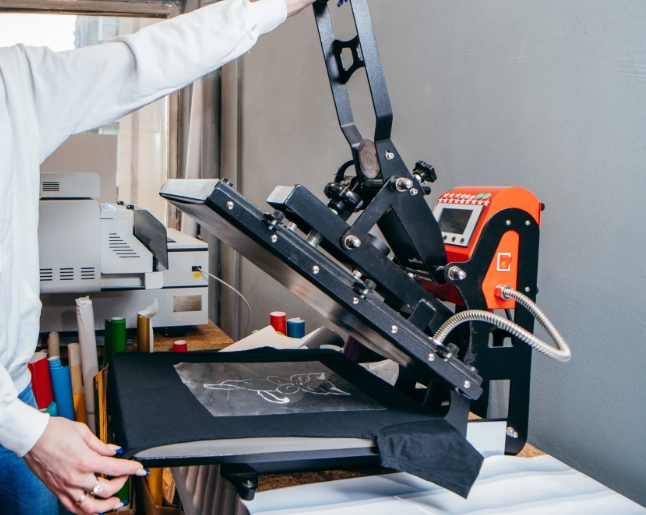

DTF printing is a revolutionary technique that transfers designs from PET film onto fabric using adhesive powder and heat pressing. Unlike DTG (Direct-to-Garment), which prints directly on fabric, or screen printing, which uses mesh and ink, DTF allows for pre-printing designs on film that can be applied later—making it ideal for on-demand production. For a full breakdown of how DTF printing works from start to finish—including materials, printer setup, and workflow—you can read our complete guide: Everything You Need to Know About the DTF Printing Process.

Key advantages of DTF prints:

• Works on diverse fabrics: cotton, polyester, rayon, canvas, nylon, silk, and more

• No pre-treatment required for most materials

• Sharp, colorful designs with a soft hand feel

• Stores well before transfer, enabling flexible production

Whether you're printing on a T-shirt, tote bag, hoodie, or performance gear, DTF adapts seamlessly—making it one of the most versatile solutions available today.

When applied correctly and cared for properly, DTF prints can last for 50 to 70 wash cycles—maintaining color vibrancy and design integrity. This estimate is based on controlled conditions that simulate home laundering, such as AATCC 61-2A testing protocols, a widely recognized standard for colorfastness and abrasion.

⚠️ Important: This level of durability assumes the use of high-quality inks, adhesives, film, and calibrated heat pressing equipment. Cutting corners on any of these can drastically shorten print life.

DTF's exceptional longevity, combined with its compatibility across fabric types, makes it a smart choice for decorators who want prints that stand the test of time—literally.

The print process is only as strong as its weakest link. Here are the core factors that determine whether your DTF print lasts five washes—or fifty:

Low-quality inks may look fine initially but will crack or fade after minimal wear. Use pigmented, fade-resistant DTF inks from trusted manufacturers.

Premium films ensure smoother release and stronger bonding. Look for high-quality matte or cold-peel films and adhesive powders that melt uniformly and bond evenly to the garment.

Small errors in time, temperature, or pressure can cause prints to peel prematurely. Most DTF prints require pressing at 150–160°C for 15–20 seconds under medium-firm pressure.

Want to get your press settings just right? This step-by-step guide on How to Make a DTF Transfer with the Right Temperature Settings will help you fine-tune your workflow for consistent results.

Smooth, tightly woven fabrics like combed cotton or polyester blends yield better adhesion. Highly elastic (spandex-heavy), silicone-coated, or waterproof fabrics may need special treatment.

Pro tip: Always test-print on unknown fabric types to avoid customer issues later.

Absolutely. DTF is not limited to basic color prints. It can accommodate:

• High-Density Prints – For a bold, tactile texture

• Glitter or Metallic Additives – To create eye-catching fashion pieces

• Elastic Formulas – Suitable for stretch garments like yoga wear

Keep in mind: the more texture or thickness you add, the more carefully you must calibrate your press settings to avoid cracking or delamination over time.

DTF printing holds up well—but how does it compare with other industry-standard methods?

| Printing Method | Average Durability | Fabric Versatility | Setup Time | Softness |

|---|---|---|---|---|

| DTF | 50–70 washes | Very High | Low | Very Soft |

| Screen Printing | 70–100 washes+ | Medium | High | Moderate |

| DTG | 30–50 washes | Low–Medium | Medium | Very Soft |

| HTV | 40–60 washes | Medium | Medium | Rigid Feel |

While screen printing may last slightly longer for industrial workwear with thick ink layers, DTF offers superior performance in color detail, fabric compatibility, and production speed. Compared to HTV, DTF eliminates the "plastic" feeling and adheres more naturally into the fibers—resulting in a print that feels more like fabric than film. Interested in UV DTF technology and how it compares with heat-transfer DTF? Check out our detailed primer: UV DTF Printing 101: The Ultimate Beginner-to-Pro Guide

Longevity isn't just about the printing process—it's about what happens after. Here's how to help your customers (and your business) get the most from every print.

• Turn garments inside out

• Use cold water and gentle cycles

• Avoid bleach, harsh detergents, and fabric softeners

• Air-dry flat whenever possible

• If using a dryer, low heat only

• Never iron directly on the print (use parchment paper or a pressing cloth if needed)

• Keep garments away from radiators, sunlight, or hot surfaces

• High temps can soften or distort the adhesive over time

• Fold neatly (not crammed)

• Keep in a cool, dry place away from UV or humidity

Include a simple DTF care card with every order to reduce complaints and increase customer satisfaction. Your print may be amazing—but its lifespan depends on what happens after it leaves your shop.

Consistency is everything when building trust with clients. Here's how to ensure your DTF output meets professional standards:

• Use high-quality films and adhesive powders designed for durability

• Fade-resistant pigment inks from reputable brands

Not sure which method to use for curing your adhesive powder? Our guide How to Perfectly Cure DTF Powder: Heat Press, Heat Gun, or Oven? compares all the options and explains when to use each.

• Heat press temp: 150–160°C

• Pressure: medium-firm

• Dwell time: 15–20 seconds, followed by 5–10 seconds post-press (if cold peel)

• Clean printheads regularly

• Inspect rollers and belts weekly

• Keep firmware updated for software-controlled DTF printers

• Test new materials in small runs

• Stay current with trends in fabric technology, ink formulation, and pressing techniques

DTF isn't just another trend—it's a printing method that's aligned with the future of custom garment decoration:

From cotton to polyester, denim to canvas—DTF handles them all. Even silk and rayon are achievable with proper settings.

50+ washes is realistic with proper execution—comparable to screen printing, but with far greater design flexibility.

No screen setup. No pre-treatment. No slowdowns. Just fast, clean, repeatable production—even for one-off jobs.

You save time, reduce labor, minimize error, and unlock new product categories (e.g., polyester activewear) for high-margin sales.

With print-on-demand, personalization, and small batch runs becoming the norm, DTF meets the moment—without sacrificing quality.

One of DTF's most underrated advantages is the ability to print and store designs on film in advance, then apply them as needed. This enables:

• Quick turnaround for urgent orders

• Efficient batch printing and order prep

• On-demand personalization with no production delays

In a fast-moving POD or retail environment, this production flexibility enhances your operational durability—even when your team is pressed for time.

While DTF may appear more expensive per transfer compared to HTV or basic DTG, it offers better long-term value due to:

• No need for costly pre-treatment (as in DTG)

• No screen creation or washout time (as in screen printing)

• Fewer misprints and reworks thanks to digital control

• Access to high-margin markets, like poly sportswear or fashion glitter prints

In terms of total cost of ownership (TCO) and return on investment (ROI), DTF offers a scalable and efficient solution for both small studios and industrial setups.

Durability, versatility, and vibrancy—DTF prints bring together everything decorators need to impress customers and build a loyal brand. While no method is indestructible, DTF delivers exceptional performance when handled with care.

From small Etsy sellers to full-scale print shops, the ability to offer prints that last, feel soft, and apply to nearly any fabric can be a game-changer. With the right setup, training, and quality control, your DTF prints won't just survive—they'll thrive.

1. How long do DTF prints last?

With proper materials and care, DTF prints can last 50–70 washes, based on AATCC 61 testing simulations.

2. Can DTF prints crack or peel?

If improperly pressed or low-quality adhesives are used, yes. But high-end DTF systems resist cracking and peeling for dozens of washes.

3. What fabrics are best for DTF printing?

Cotton, polyester, tri-blends, rayon, and even silk. Technical fabrics like nylon or waterproof materials may need pre-treatment.

4. How do I fix a cracked DTF print?

If caught early, re-pressing at the correct temp/pressure with parchment paper may restore adhesion.

5. Is DTF safe for baby clothing?

Yes—if using non-toxic, skin-safe inks and adhesives. Always confirm safety standards before selling to sensitive markets.

6. Does DTF feel stiff like HTV?

No. DTF prints bond seamlessly into fabric fibers, offering a softer, more natural feel than HTV.

7. Is DTF eco-friendly?

Some DTF films and inks are designed to meet basic environmental standards. Always check with your supplier for compliance details.

8. How does DTF compare to screen printing in wearability?

DTF provides equal comfort and good durability in daily wear—though screen printing still excels in extreme abrasion scenarios.

Ready to elevate your fabric printing business with reliable DTF supplies? Hanze offers high-performance DTF printers, film, ink, and powder designed for consistent, scalable production across all fabric types. Whether you're expanding capacity or optimizing print quality, our solutions support OEM customization and bulk procurement. Contact us today to streamline your supply chain and power your production with confidence.